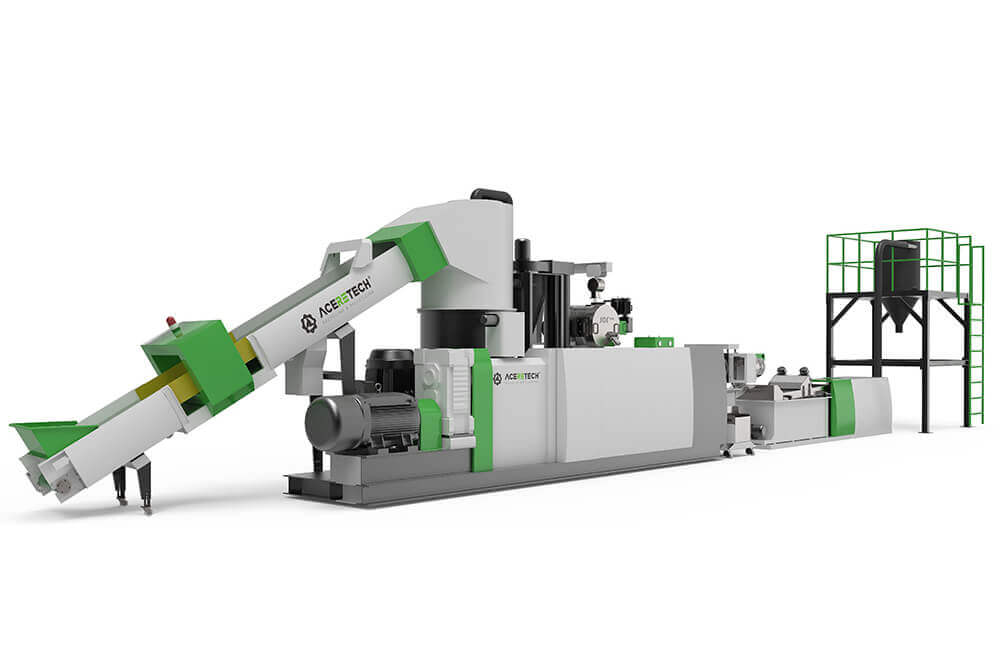

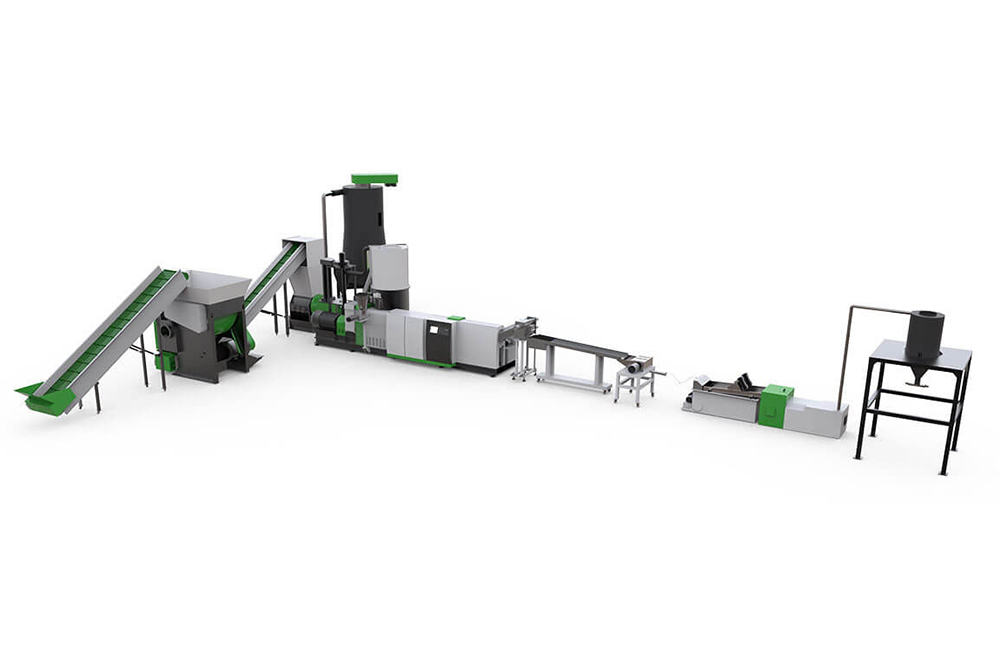

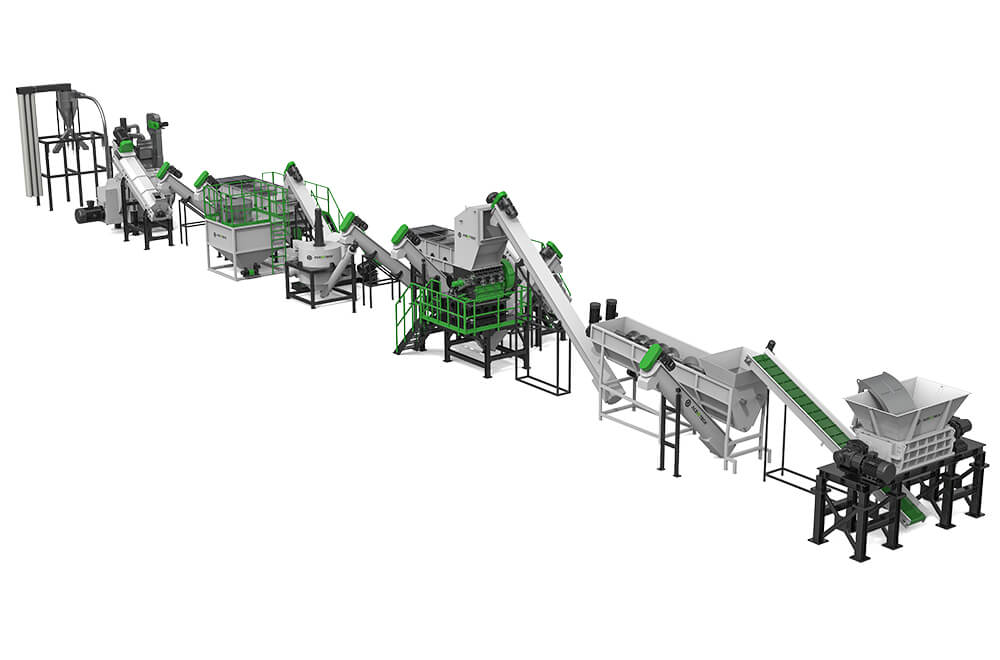

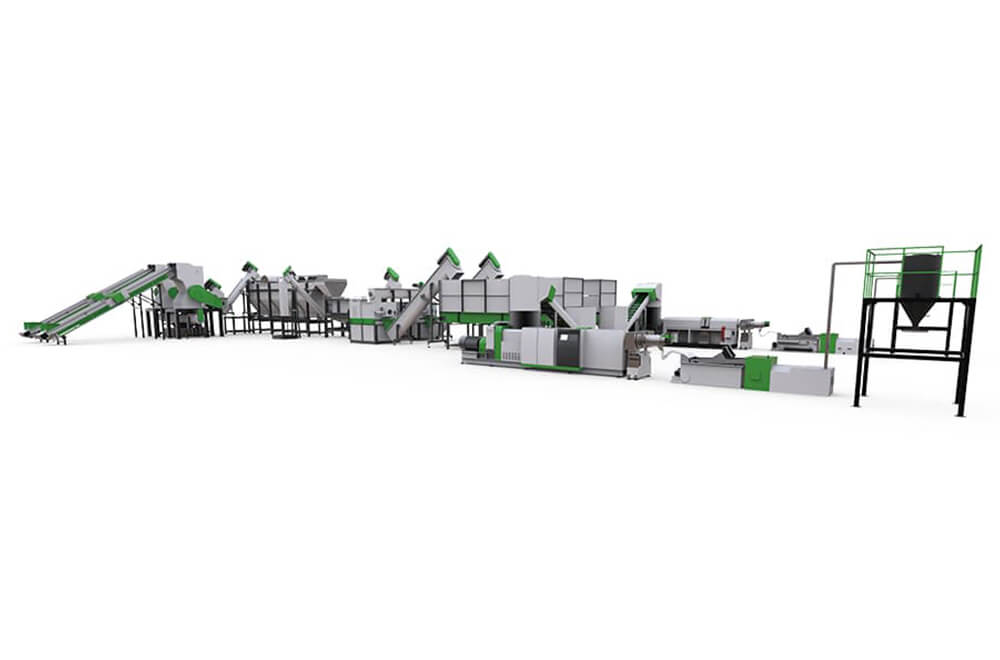

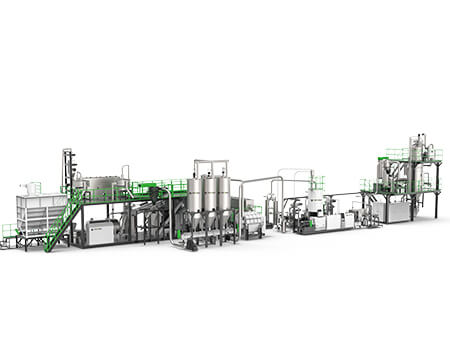

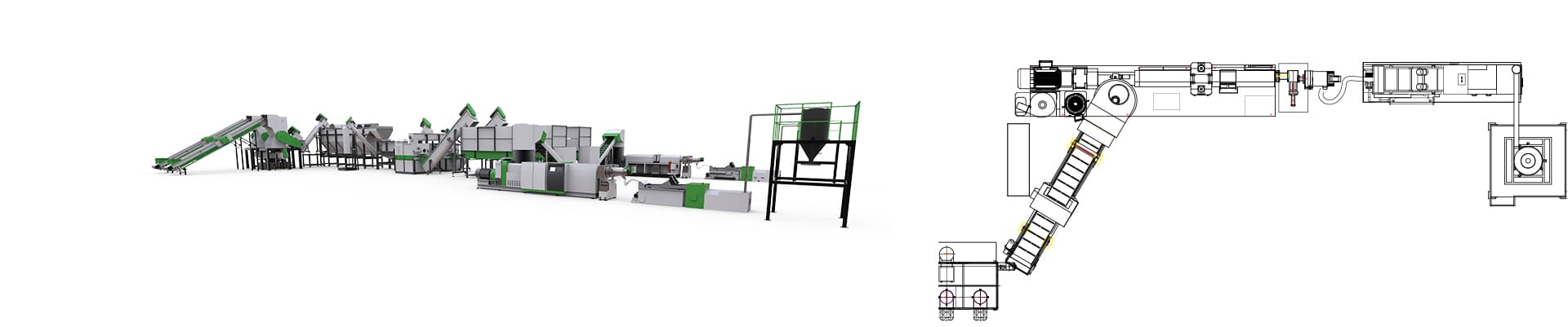

AWS-PE塑料PE膜回收清洗线机

产品介紹

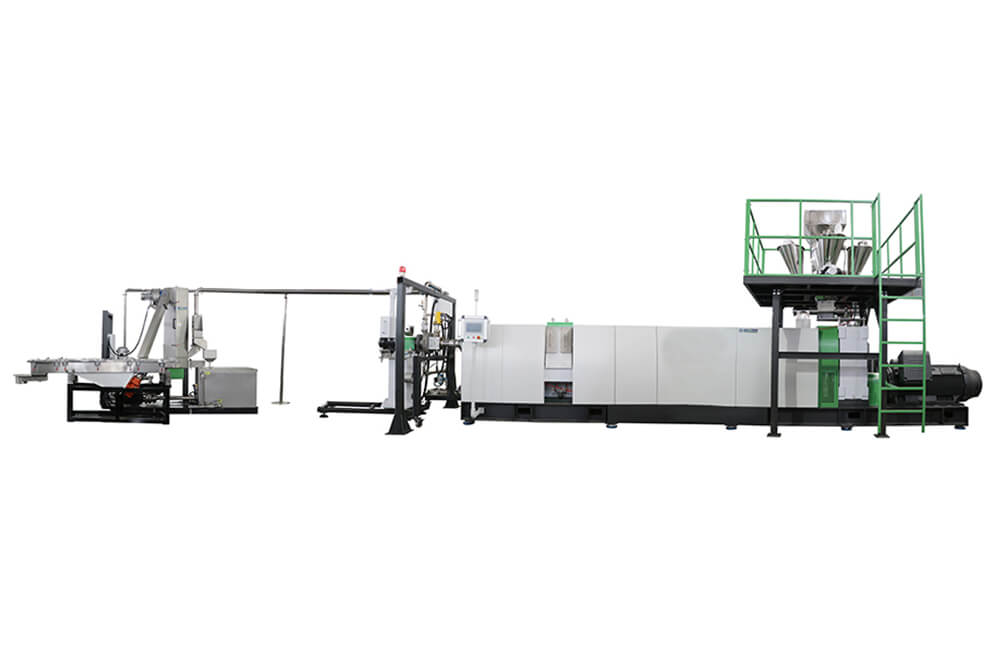

产品参数

|

设备参数 |

|||

|

型号 |

容量 |

容量 |

设备占地面积 |

|

AWS PE 05 |

500kg/h |

150KW |

120m 2 |

|

AWS PE 10 |

1000kg/h |

190KW |

260m 2 |

|

AWS PE 20 |

2000kg/h |

290KW |

380m 2 |

|

单位能耗 |

|||

|

内容 |

每吨瓶子的平均能耗 |

||

|

电 |

180-250KW |

||

|

水 |

1.5-3T |

||

|

压缩的空气 |

0.5-1m 3 |

||

|

蒸汽(可选) |

0-100KG |

||

|

洗涤剂(可选) |

0-5KG |

||

.jpg)

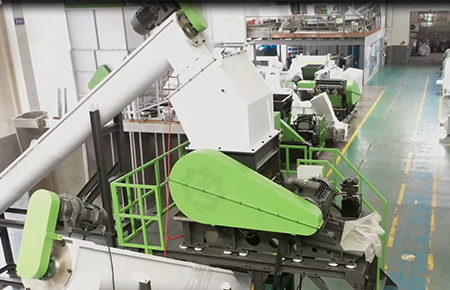

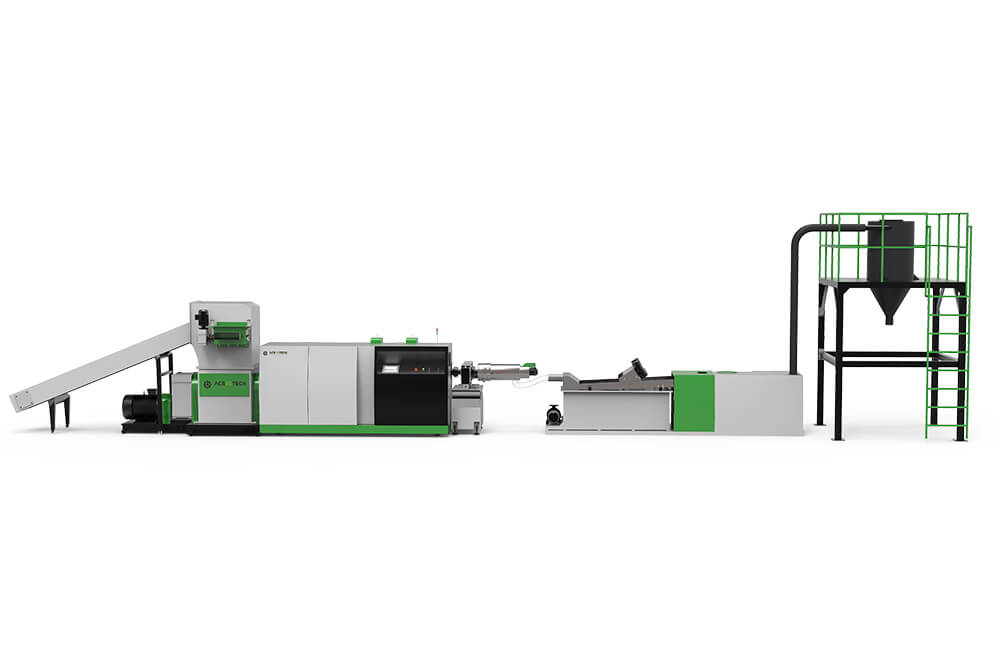

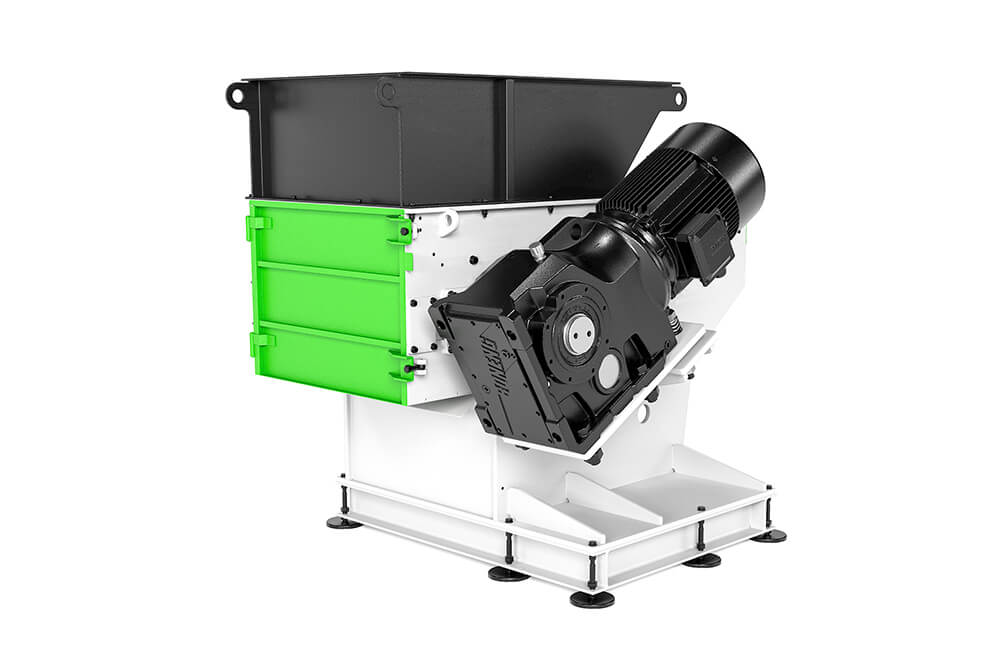

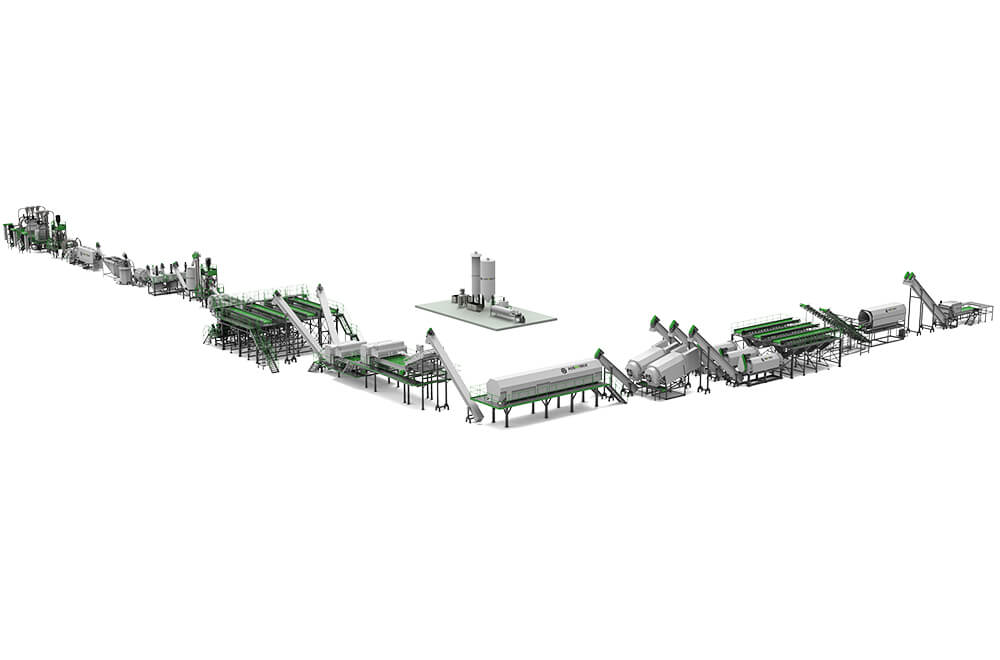

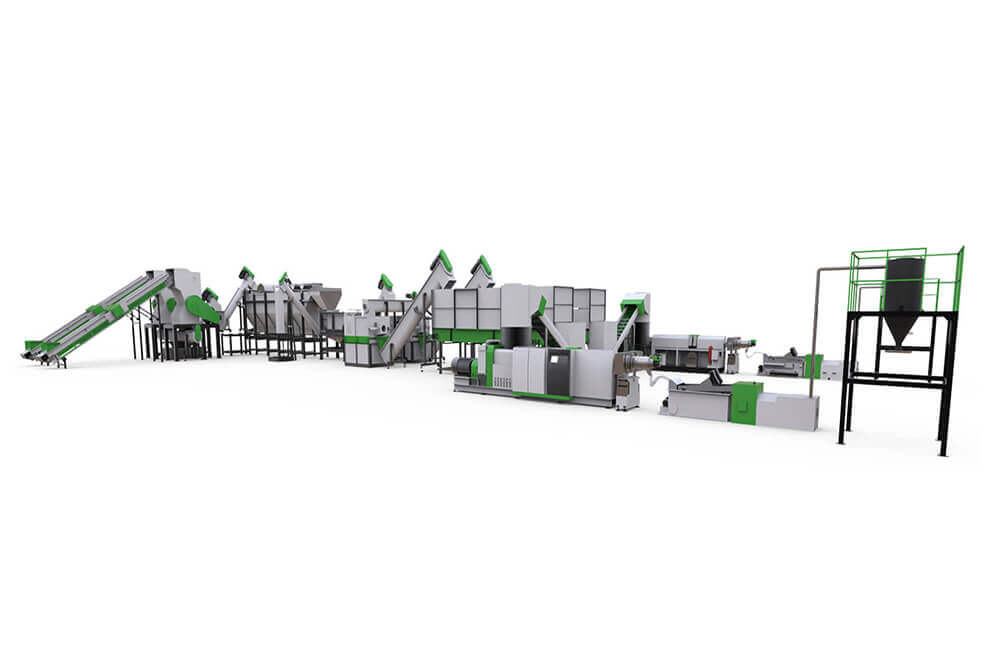

进料输送机到撕碎机

内置重型版本;

带负载相关控制装置,避免撕碎机超喂;

金属探测器可选,用于探测金属污染物以保护碎纸机;

皮带输送机可以是PVC/橡胶材料;

带式输送机的速度由变频器控制。

.jpg)

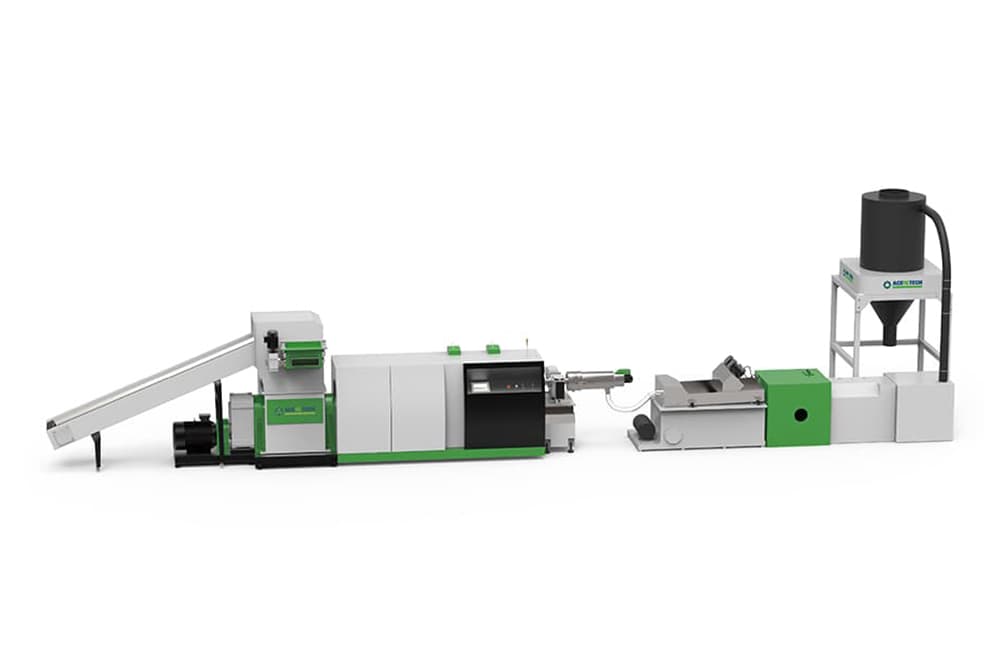

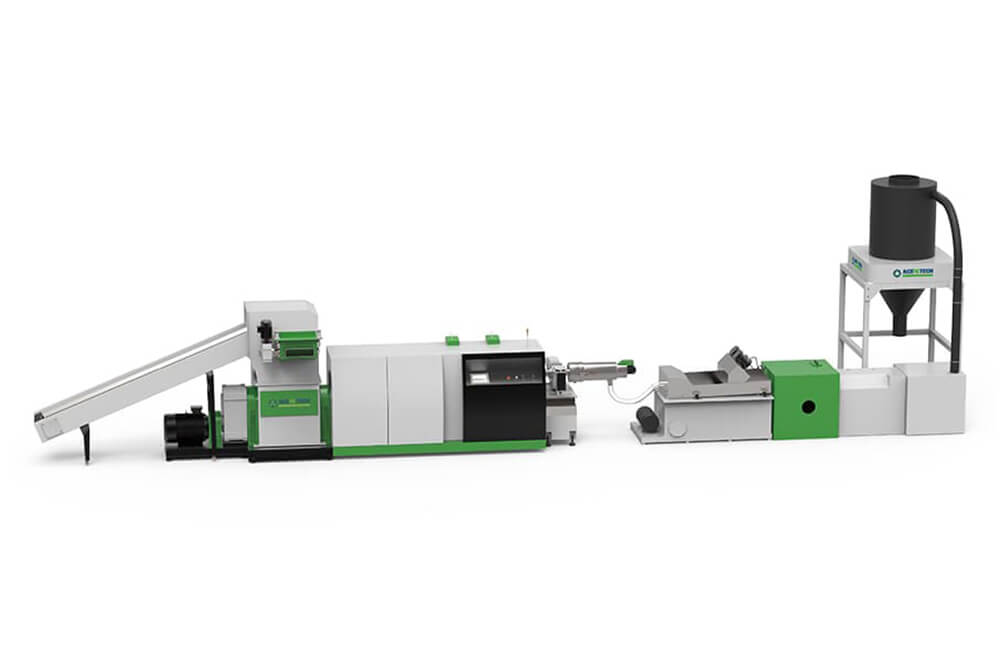

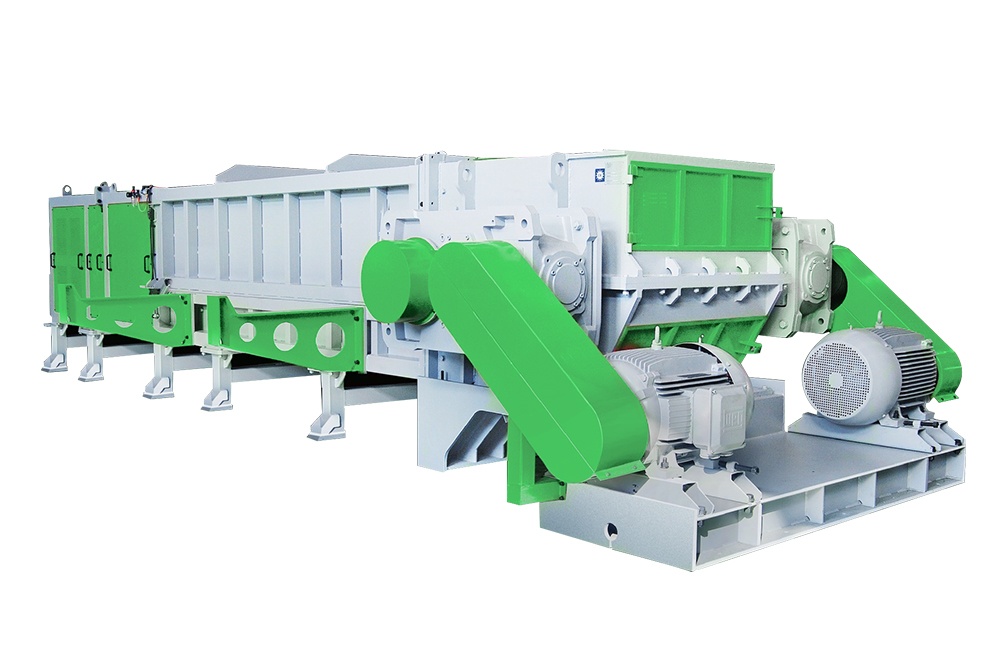

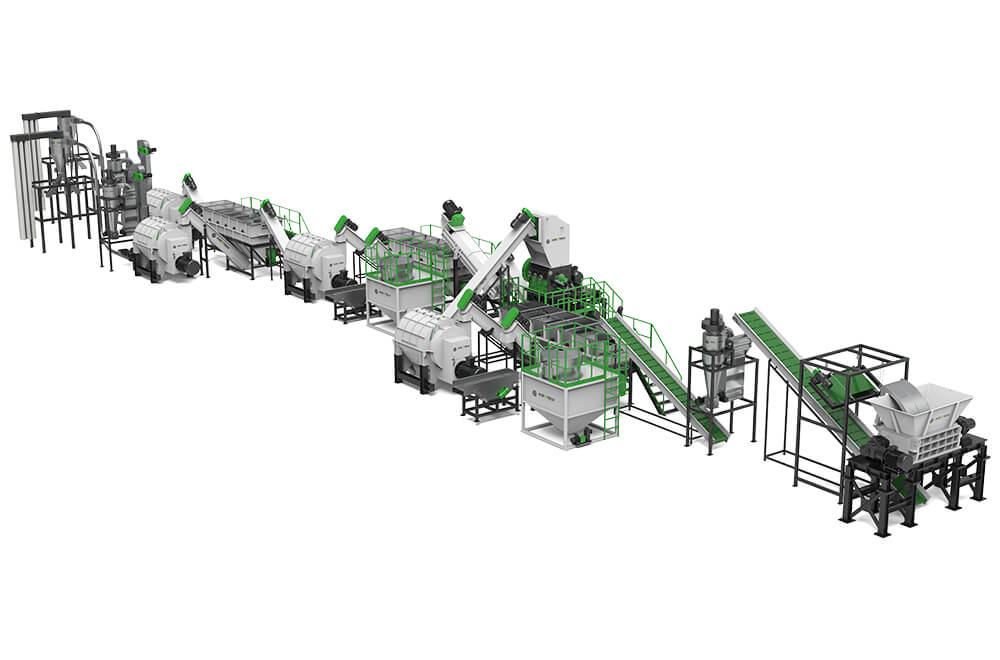

优点:

切割室内空间增加 35%;

内置液压油缸;

可变的更快的柱塞运动;

比传统碎纸机占用的空间更少

带水平柱塞;

封闭式切割室,防止材料飞出。

1. 用于输送破碎机中的薄片

2. PVC带

3. 采用变频调速

.jpg)

磁选带可以选装在撕碎机的卸料皮带机上,它可以通过永磁体自动去除黑色金属。

.jpg)

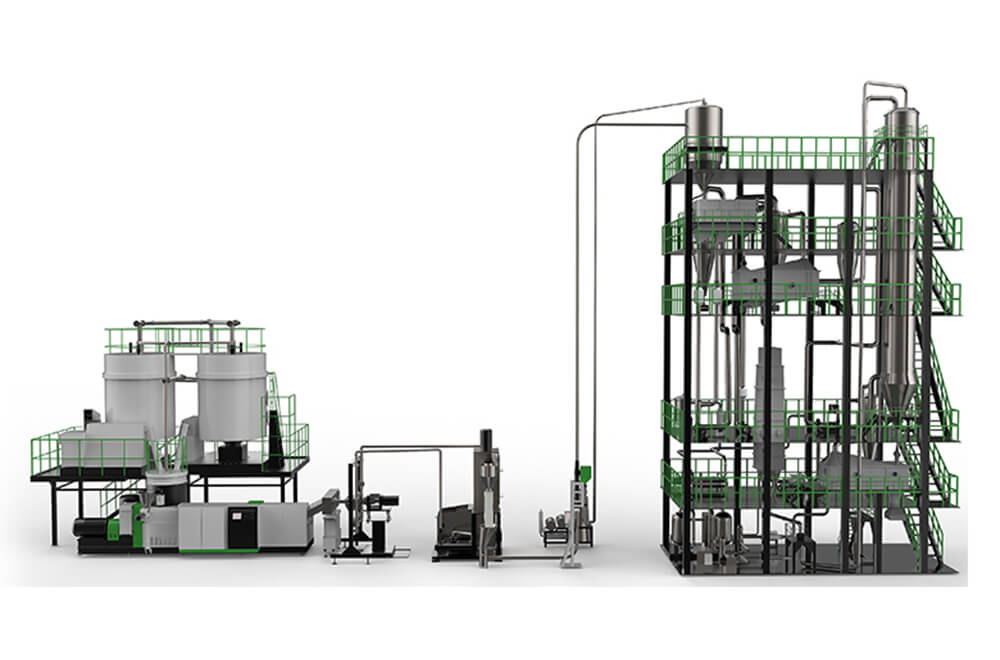

分离罐,内置不锈钢;卸料桶; “重物”双排放系统,电动阀;带气动进水阀,通过电子给料器自动控制液位;配备压缩机鼓风机,将压缩空气注入罐底;带工作平台;节水节能设计。

用水冲入粉碎; 3/5/7转子设计;外腔调刀;低噪声。

.jpg)

摩擦洗作为坚固的洗涤装置,可去除大部分污染物;外壳采用不锈钢焊接结构;加强型、低碳钢和高速转子;超大尺寸的外置轴承;不锈钢筛网,孔径3mm;用于塑料片的不锈钢进料和卸料斗;底部排水。

.jpg)

用于从 PE/PP 薄片中分离比重 > 1 g/cm³ 的污染物或其他塑料;带旋入式和旋出式;内桨的特殊设计,保证重杂质有足够的沉淀;不锈钢SUS304机身;带气动进水阀,通过电子感应器自动控制液位。

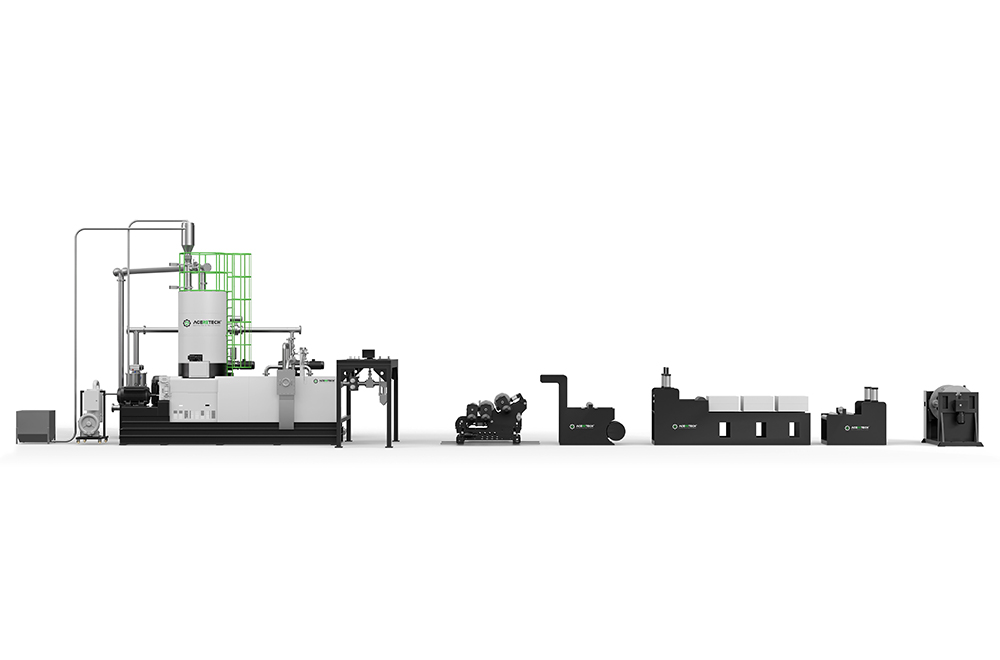

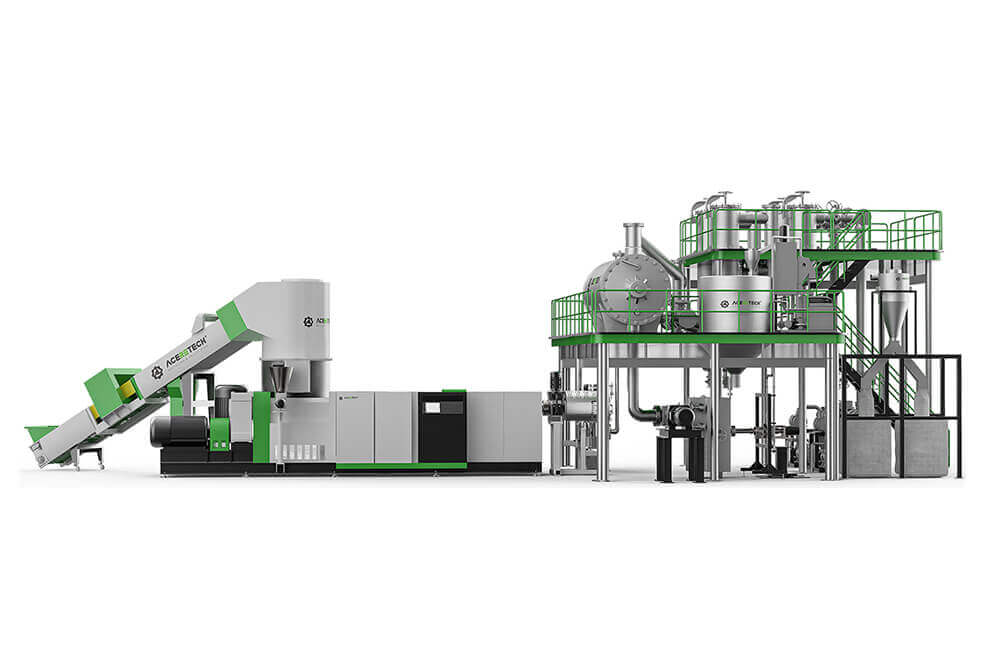

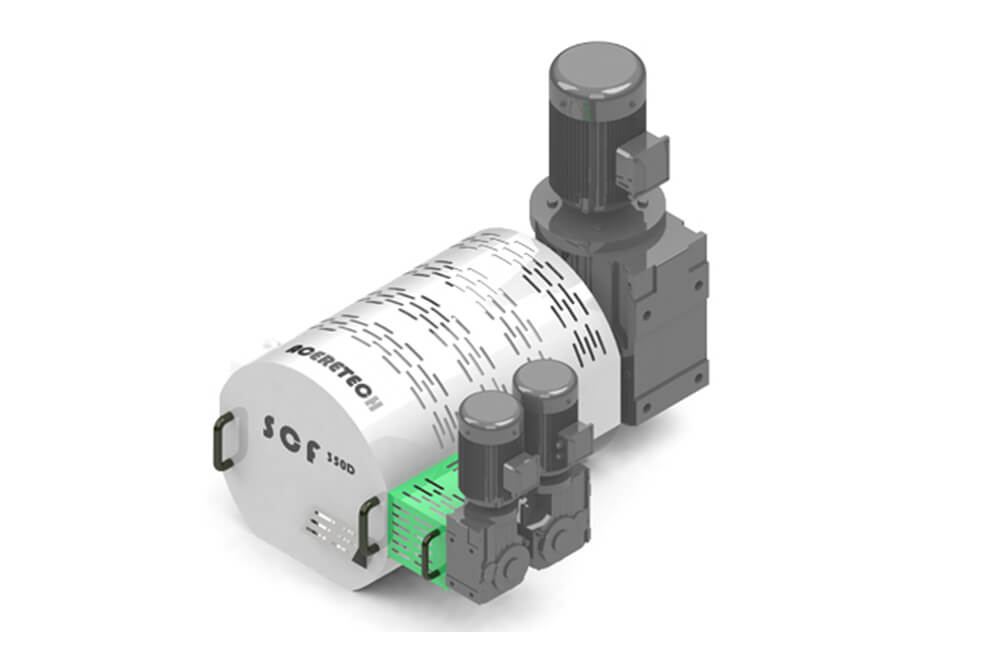

处理不同的物料,我们有不同种类的干燥系统,挤压机或离心干燥机和管道干燥机,取决于客户的要求。对于薄膜等软质材料,我们可以使用挤压机或离心干燥机,干燥后物料水分控制在5-8%,对于硬质塑料材料,我们可以使用离心干燥机和管道干燥系统,干燥后物料水分将小于 1%。

.jpg)

为保证下游挤出造粒线的不间断工作和稳定进料,我们将使用缓冲料仓来储存洗涤后的材料。特殊设计确保物料不堵塞,料仓顶部设有旋风除尘装置。

电控元件:(施耐德),例如断路器、交流触点、按钮、指示灯;用于整个系统的电气控制;安全联锁原理;所有电气单元:LS、施耐德、ABB。

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

联系我们

联系我们